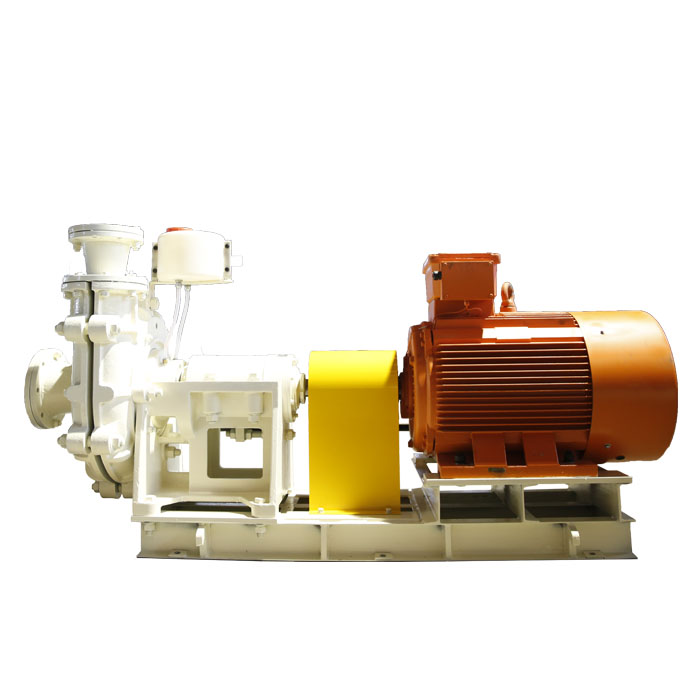

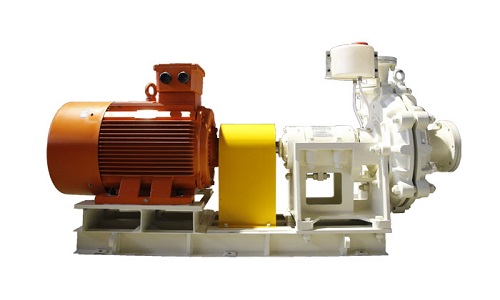

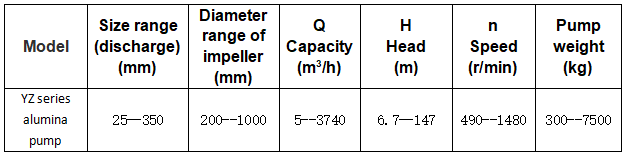

YZS(D) series alumina technological process slurry pump

Introduction:

Slurry pump is the main equipment for conveying slurry in alumina technological process. Its normal operation is the guarantee for the steady increase of alumina output. At present, the domestic slurry pumps are general machinery, in the application of alumina process, the adaptability of the products will be limited to some degrees. For example: the service life of the pump wet parts, the sealing effect of the pump shaft seal, and the standardization of pump accessories. Our company comprehensively and systematically analyzed the effect of the slurry pump used in the alumina process at home and abroad, and adopted the strategy of promoting strengths and avoiding shortcomings. According to the different characteristics of the alumina process slurry, we jointly designed and manufactured YZS and YZD series alumina technological process slurry pumps with some domestic well-known universities, which has obtained five national invention patents and filled the gap of the alumina technological process slurry pump in China.

Main features

1. The fluid molded lines of the impeller, volute casing, and liner plates of the wet parts of the YZS and YZD series alumina process slurry pumps all adopt the solid-liquid two-phase flow hydraulic model developed by some prestigious universities according to the characteristics of the alumina slurry. This product design is efficient and cavitation-resisting, which is more resistant to the abrasion than the slurry pump used in the alumina industry.

2. The wet parts of the pump have a high degree of compatibility and interchangeability; although the fluid molded lines of the wet parts of the YZS and YZD series alumina process slurry pumps are different from the current slurry pumps used in the alumina industry, they can be interchanged. It meets the needs of use rs for the wet parts and spare parts of YZS and YZD series alumina process slurry pumps.

3. The shaft seal of the YZS and YZD series alumina process slurry pump is a combined structure of "dynamic seal and mechanical seal". This combined structure design is the first patent technology in China, which can make the shaft seal without leakage for a long time. The service life of this shaft seal is several times to dozens of times that of mechanical seal and packing seal.

4. The wet part material of YZS, YZD alumina process slurry pumps is KmTBCra28 - a high-chromium alloy wear-resisting material, whose Rockwell hardness can reach 62.